Raptor vs Merlin: Key Differences

Explore the innovative designs and distinct purposes of SpaceX's Raptor and Merlin engines, highlighting their roles in space exploration.

SpaceX's Merlin and Raptor engines power its rockets for different missions, showcasing distinct designs and purposes. Here's a quick breakdown:

- Merlin Engine: Powers Falcon 9 and Falcon Heavy rockets. Uses RP-1 (refined kerosene) and liquid oxygen (LOx). Known for simplicity, reliability, and low cost. Produces 205,000 lbf of thrust and supports up to 10 reuses per engine.

- Raptor Engine: Powers the Starship program. Runs on liquid methane (CH₄) and LOx, enabling Mars fuel production. Features a full-flow staged combustion cycle for higher efficiency. Produces 620,000 lbf of thrust and is designed for 50+ reuses.

Quick Comparison

| Feature | Merlin | Raptor |

|---|---|---|

| Thrust (Sea Level) | 205,000 lbf | 620,000 lbf |

| Fuel | RP-1/LOx | Methane/LOx |

| Combustion Cycle | Open-cycle gas generator | Full-flow staged combustion |

| Reusability | ~10 flights | ~50+ flights |

| Primary Use | Earth orbit (Falcon rockets) | Interplanetary (Starship missions) |

| Cost per Engine | <$1 million | ~$2 million (early versions) |

Key Takeaway

Merlin engines are optimized for cost-effective, reliable orbital launches, while Raptor engines are designed for high performance, efficiency, and Mars colonization. Together, they represent SpaceX's dual focus: current commercial launches and future interplanetary exploration.

Is SpaceX's Raptor engine the king of rocket engines?

Design Differences Between Raptor and Merlin

SpaceX’s Raptor and Merlin engines reflect two very different design approaches - one prioritizes tried-and-tested reliability and cost efficiency, while the other focuses on cutting-edge performance designed for ambitious space exploration.

Fuel Systems

One of the standout differences lies in their fuel systems. Merlin engines use RP-1, a refined kerosene, combined with liquid oxygen (LOx). This choice leverages the benefits of RP-1’s high density and storage at near room temperature, making it practical and efficient for many missions.

Raptor engines, on the other hand, use a methalox fuel system, burning sub-cooled liquid methane (CH4) with LOx. This setup operates at a roughly 3.8-to-1 oxidizer-to-fuel ratio and requires handling at cryogenic temperatures, which adds complexity. But methane brings unique advantages, especially for SpaceX’s long-term vision of Mars colonization. Methane can be produced on Mars using the Sabatier reaction, making it a sustainable fuel source for interplanetary missions.

Elon Musk explained the reasoning behind this switch:

"The energy cost of methane is the lowest and it has a slight Isp (Specific Impulse) advantage over Kerosene, And it does not have the pain in the ass factor that hydrogen has."

- Elon Musk

Methane also burns cleaner compared to RP-1, significantly reducing carbon buildup inside the engine. This cleaner combustion helps prevent coking, a process where carbon deposits can degrade engine performance over time. Next, let’s look at how their combustion cycles set these engines even further apart.

Combustion Cycles

The engines’ combustion cycles showcase another major difference in their design philosophies. Merlin engines use an open-cycle gas generator system. This approach vents excess fuel, prioritizing simplicity and ease of manufacturing over maximum efficiency.

In contrast, the Raptor engine employs a closed-cycle, full-flow staged combustion system. Here, all propellants pass through pre-burners before entering the main combustion chamber, achieving nearly complete combustion at 99% efficiency. John F. Lindner elaborated on this advanced design:

"The Raptor is a closed-cycle and full-flow staged-combustion engine as all of its propellants flow through the pre-burners (aka gas generators) to fully burn in the combustion chamber in the optimal ratio and exhaust out the nozzle for maximum efficiency."

- John F. Lindner

This system allows the Raptor to operate at extreme pressures - up to 250 bar, with the Raptor 3 pushing this even further to 350 bar. The result? The Raptor’s thrust far outpaces that of the Merlin 1D. For comparison, Raptor 2 generates 230 tonnes of thrust, a significant leap from Raptor 1’s 185 tonnes .

Performance and Efficiency Comparison

The Raptor and Merlin engines, with their distinct designs, showcase strikingly different approaches to performance and efficiency. These differences stem from their unique engineering philosophies and the specific missions they aim to fulfill.

Thrust and Power Output

The Raptor engines deliver substantially higher thrust compared to the Merlin engines, with the Raptor 3 generating nearly three times the thrust of the Merlin 1D. Here's a closer look at the numbers:

| Engine | Thrust (Sea-Level) | Thrust (Vacuum) | Thrust-to-Weight Ratio |

|---|---|---|---|

| Merlin 1D | 205,000 lbf (914 kN) | 210,000 lbf (934 kN) | 176–180 |

| Raptor 1 | 408,000 lbf (1.81 MN) | – | 88.94 |

| Raptor 2 | 507,000 lbf (2.26 MN) | 569,000 lbf (2.53 MN) | 141.1 |

| Raptor 3 | 617,000 lbf (2.75 MN) | 670,000 lbf (2.98 MN) | 183.6 |

The progression from Raptor 1 to Raptor 3 highlights SpaceX's focus on increasing thrust. At sea level, Raptor 3 reaches 617,000 pounds of thrust, far surpassing the Merlin 1D. Yet, Merlin engines hold their ground with impressive thrust-to-weight ratios, especially in vacuum conditions.

Fuel Efficiency and Waste Reduction

The Raptor engine's closed-cycle, full-flow staged combustion system gives it a notable edge in efficiency. By channeling all propellants through the turbines, it achieves a higher specific impulse - Raptor Vacuum targets approximately 380 seconds, compared to the Merlin 1D Vacuum's 348 seconds.

Additionally, the Raptor engine's use of liquid methane as fuel leads to cleaner combustion than the Merlin's RP-1 kerosene. This reduces carbon buildup, which could lower maintenance demands over time. The oxidizer-to-fuel ratio of 3.8 to 1, optimized for the methalox combination, further enhances its efficiency. However, this advanced design comes with added complexity.

Complexity vs. Simplicity

The contrast between the Raptor and Merlin engines becomes even clearer when comparing their operational complexity. Raptor's incredible 300-bar chamber pressure, significantly higher than Merlin's 97 bar, allows for rapid reuse - up to 50 flights - while reducing the need for heat shields. However, this requires cutting-edge engineering.

Elon Musk acknowledged the challenges of refining Raptor 3:

"Important to note that the induced mass (mass required by a given engine design that is not the engine itself) of Raptor 3, while far better than Raptor 2, still has a lot of room for improvement."

Meanwhile, the Merlin engine's simpler gas generator cycle prioritizes reliability and quick turnaround times. This approach has proven effective, as Falcon 9 boosters frequently complete multiple missions with minimal refurbishment.

These differences highlight SpaceX's dual strategy: leveraging advanced technology with the Raptor for future missions while relying on the Merlin's proven dependability to maintain its strong position in the market.

Applications and Use Cases

The design and performance of Merlin and Raptor engines highlight how SpaceX strategically tailors its technology for specific missions. Each engine plays a unique role in advancing the company’s ambitious goals.

Merlin's Role in Falcon Rockets

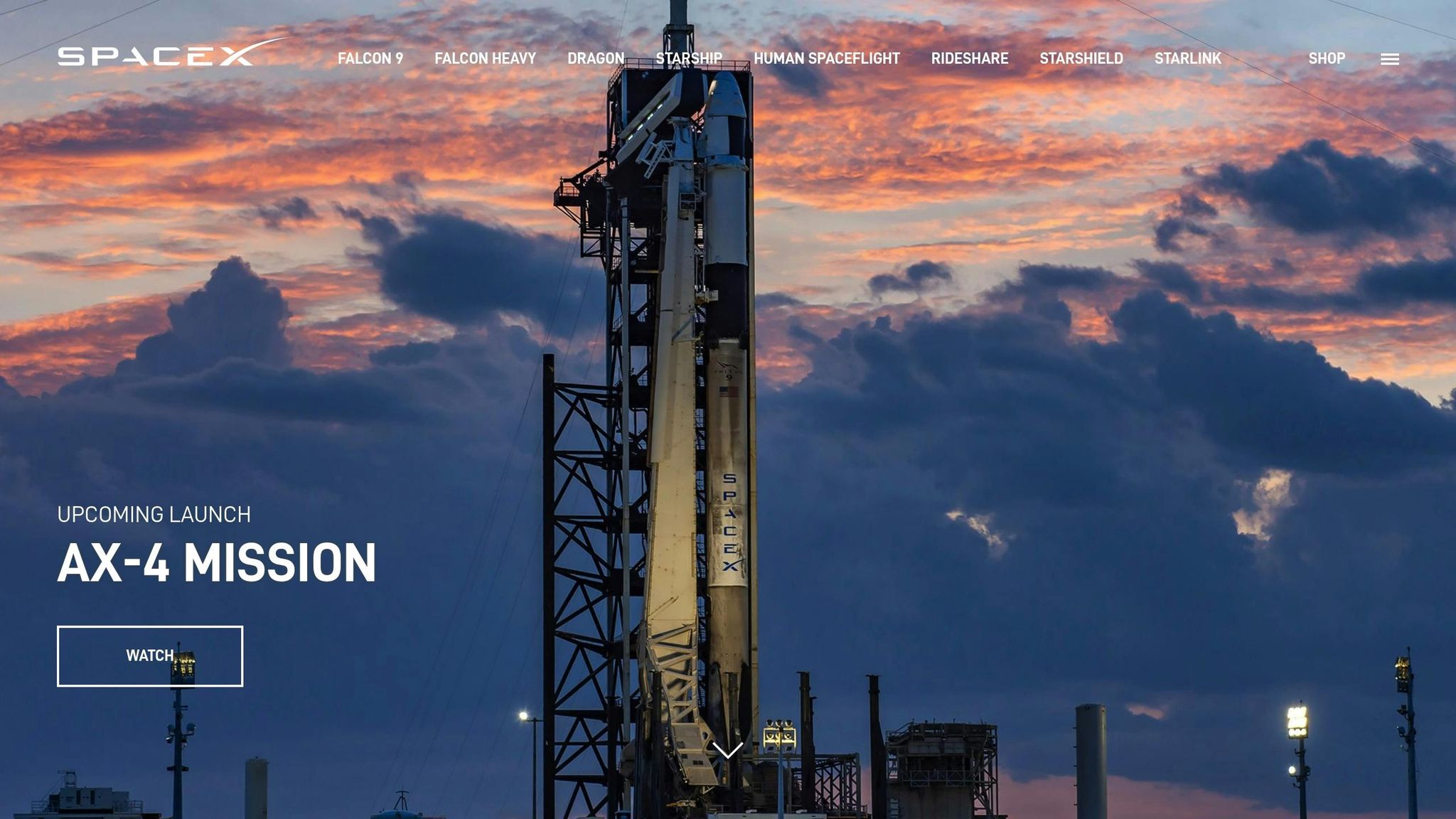

Merlin engines are the backbone of SpaceX's commercial launch operations, powering both the Falcon 9 and Falcon Heavy rockets. Falcon 9, a reusable two-stage rocket, is crafted to efficiently transport payloads and people into orbit and beyond.

Merlin engines excel in launching commercial satellites. Falcon 9 can carry up to 50,265 lbs (22,800 kg) to low Earth orbit (LEO) and 18,298 lbs (8,300 kg) to geostationary transfer orbit (GTO). Since January 2020, most Falcon 9 missions have been dedicated to deploying Starlink satellites. For example, in January 2023, a single launch sent 56 Starlink v1.5 satellites into a 530 km orbit.

Merlin's reliability also shines in missions involving the International Space Station (ISS). Falcon 9 has consistently transported Dragon spacecraft for crewed and cargo missions. As of May 31, 2025, the Falcon 9 family has achieved 494 launches with 491 full mission successes.

For heavier payloads, Falcon Heavy steps in. It can lift nearly 141,000 lbs (64 metric tons) to LEO. Recent notable missions include the July 29, 2023 launch of the 20,282 lb (9,200 kg) Jupiter-3 satellite to GTO and the October 14, 2024 launch of NASA's Europa Clipper for studying Jupiter’s moon Europa .

| Vehicle | Payload to LEO | Payload to GTO | Payload to Mars |

|---|---|---|---|

| Falcon 9 | 50,265 lbs (22,800 kg) | 18,298 lbs (8,300 kg) | 8,862 lbs (4,020 kg) |

| Falcon Heavy | 140,660 lbs (63,800 kg) | 58,862 lbs (26,700 kg) | 37,038 lbs (16,800 kg) |

While Merlin engines dominate SpaceX's current orbital missions, Raptor engines are designed for the next frontier: interplanetary travel.

Raptor's Role in Starship Missions

Raptor engines power SpaceX's Starship system, which is built for deep-space exploration and interplanetary missions. A key feature of the Raptor is its methane-based fuel system, which offers a major advantage for Mars missions, as methane can be produced on Mars itself.

The long-term vision for Raptor revolves around Mars colonization. By enabling the use of locally sourced fuel, Raptor makes round-trip missions to Mars feasible. This aligns with SpaceX’s goal of establishing a permanent human settlement on the Red Planet. The engine’s full-flow staged combustion cycle ensures the efficiency needed for such extended missions.

Beyond Mars, Raptor engines are crucial for broader deep-space exploration. With nearly three times the thrust of the Merlin 1D engine, Raptor enables much larger payloads to escape Earth’s gravity. Its vacuum-optimized model achieves a specific impulse of about 380 seconds, making it highly efficient for long-duration missions.

Raptor engines are also being developed for point-to-point Earth transportation, adhering to reliability standards comparable to commercial aviation. Their design focuses on rapid reuse with minimal maintenance, a critical factor for frequent deep-space missions.

As SpaceX continues to refine Raptor’s capabilities, the engine's increasing thrust underscores its role in meeting the demands of ambitious interplanetary missions.

While Merlin engines dominate the current commercial spaceflight market, Raptor engines are driving SpaceX’s vision for humanity’s future beyond Earth. Together, these engines represent two complementary strategies: Merlin ensures SpaceX’s leadership in orbital launches and ISS missions, while Raptor lays the groundwork for interplanetary exploration and the dream of Mars colonization.

Evolution of SpaceX's Engine Technology

SpaceX's progression from the Merlin to the Raptor engines marks a groundbreaking shift in modern rocketry. This transformation showcases the company's journey from achieving reliable orbital launches to pushing the boundaries of interplanetary exploration. Along the way, SpaceX has redefined engine performance while tackling complex design challenges.

From RP-1 to Methane

The transition from RP-1 kerosene, used in Merlin engines, to methane for Raptor engines was a deliberate move aligned with SpaceX's vision for Mars colonization. While RP-1 was effective for Earth-orbit missions, it presented a maintenance challenge due to carbon deposits left on reusable components. Methane, on the other hand, burns cleaner, reducing carbon buildup and extending hardware reusability. It also offers slight gains in energy efficiency and specific impulse.

The Raptor engine’s oxidizer-to-fuel ratio of approximately 3.8 to 1 plays a key role in optimizing performance. Methane's choice is strategic for future missions, as Raptor engines are being developed to meet stringent safety standards, even for point-to-point Earth transportation.

Challenges and Advances

Switching to methane brought clear advantages but also introduced significant engineering challenges. The leap from Merlin’s simpler open-cycle gas generator system to Raptor’s full-flow staged combustion cycle added layers of complexity. For instance, the Raptor's methane pump alone requires 25 MW (37,550 hp) of power, while the oxygen pump demands 34 MW (45,590 hp).

The development phase was grueling. Over 50 Raptor engine chambers melted, and more than 20 engines exploded during testing. In late 2021, Elon Musk highlighted the urgency of overcoming these challenges in a company-wide email:

"Unless you have critical family matters or cannot physically return to Hawthorne, we need all hands on deck to recover from what is, quite frankly, a disaster."

SpaceX faced immense pressure to ramp up production, aiming for a Starship flight rate of at least once every two weeks to avoid financial setbacks.

To tackle these hurdles, SpaceX adopted advanced manufacturing techniques, including 3D printing, which now accounts for 40% of the Raptor engine’s components. This approach enabled faster prototyping and allowed engineers to create intricate designs that traditional methods couldn't achieve.

The Raptor engine also boasts several technical breakthroughs. It targets a chamber pressure of 30 MPa (300 bar) and uses a spark ignition system instead of hypergolic ignition cartridges, enabling unlimited restarts without consumable igniters.

SpaceX’s rapid iteration is evident in the evolution of the Raptor engine:

| Specification | Raptor 1 | Raptor 2 | Raptor 3 |

|---|---|---|---|

| Thrust-to-Weight Ratio | 88.94 | 141.1 | 183.6 |

| Weight vs. Raptor 1 | Baseline | Lighter | 36% lighter |

| Thrust vs. Raptor 1 | Baseline | Higher | 51% more thrust |

While Merlin engines were designed for 10–100 launches, Raptor engines aim for 1,000 flights - an essential milestone for Mars missions. These advancements underline SpaceX’s dedication to creating engines capable of supporting sustainable interplanetary travel.

SpaceX President and COO Gwynne Shotwell summed up the long-term vision for Raptor engines:

"Raptor will be able to deliver 'long life... and more benign turbine environments'."

This relentless drive for innovation positions SpaceX as a leader in aerospace. For those tracking SpaceX's progress, such as through resources like the SpaceX Stock Investment Guide, the evolution of its engines offers a window into the company’s technological edge and its ambitious goals in commercial spaceflight and beyond.

Conclusion: Raptor vs Merlin

The comparison between SpaceX's Raptor and Merlin engines showcases two distinct engineering approaches tailored to different mission objectives. Merlin engines have been the dependable backbone of SpaceX’s success, powering Falcon 9 and Falcon Heavy missions with their RP-1 and liquid oxygen propellant system. These engines helped establish SpaceX’s reputation in the commercial space industry. On the other hand, the Raptor engine represents a bold step forward, designed specifically for interplanetary missions. By using liquid methane and oxygen in a full-flow staged combustion cycle, it brings a whole new level of performance and capability.

The performance differences between these engines are striking. The Raptor 3 delivers 620,000 lbf of thrust at sea level, far surpassing the Merlin 1D’s 205,000 lbf. This means a Super Heavy booster needs just 33 Raptor engines to achieve the same thrust that would require 100 Merlin engines. Raptor’s engineering complexity is equally impressive, with a record-breaking chamber pressure of 350 bar and an efficiency target of 99%. As Elon Musk put it, the Raptor operates "near the limits of physical constraints".

| Engine Comparison | Merlin 1D | Raptor 3 |

|---|---|---|

| Thrust (Sea Level) | 205,000 lbf | 620,000 lbf |

| Fuel System | RP-1/LOX | Methane/LOX |

| Combustion Cycle | Open-cycle gas generator | Full-flow staged combustion |

| Primary Mission | Earth orbit operations | Interplanetary travel |

| Reusability | Reusable | Designed for rapid reuse |

This table highlights SpaceX’s move from reliable orbital launches to ambitious interplanetary exploration. Raptor’s use of methane not only enhances performance but also enables in-situ fuel production on Mars. Using the Sabatier reaction, Mars’ CO₂-rich atmosphere and subsurface water ice can be converted into methane and oxygen, making return missions and a sustainable Mars colony feasible.

Key Takeaways for Investors

The transition from Merlin to Raptor is not just a technological upgrade - it’s a strategic shift that underpins SpaceX’s long-term vision. The company’s ability to reduce Raptor manufacturing costs to under $250,000 per engine demonstrates its focus on affordability, which could reshape the economics of space travel.

SpaceX’s rapid development process is also worth noting. The Raptor 3 boasts 51% more thrust and 36% less weight compared to the Raptor 1. These advancements directly impact mission costs and expand operational capabilities, reinforcing SpaceX’s competitive edge.

With its dual-engine strategy, SpaceX is uniquely positioned in the aerospace industry. While Merlin engines continue to drive Falcon missions, the Raptor engine unlocks new possibilities - from lunar exploration and Mars colonization to potential Earth-based point-to-point travel. NASA’s selection of Starship for the Artemis 3 mission in 2026 further validates the commercial potential of Raptor technology.

For those monitoring SpaceX’s investment opportunities, such as through the SpaceX Stock Investment Guide, this comparison highlights the company’s technological leadership and long-term ambition. SpaceX is not just building rockets; it’s shaping the future of the space economy.

FAQs

Why does the SpaceX Raptor engine use methane instead of RP-1 like the Merlin engine?

SpaceX chose methane as the fuel for its Raptor engine because it offers some clear advantages over RP-1, the refined kerosene used in the Merlin engine. One major benefit is that methane burns much cleaner, resulting in less carbon buildup inside the engine. This reduces maintenance needs and extends the engine's lifespan - an essential factor for SpaceX's focus on reusability.

Methane also delivers better efficiency in terms of specific impulse (a measure of how effectively a rocket uses its fuel), making it well-suited for extended missions, like journeys to Mars. Another advantage is its ease of storage and the potential to produce it on Mars through in-situ resource utilization, which ties directly into SpaceX's vision for interplanetary travel. While RP-1 has been a dependable choice for the Merlin engine, it tends to leave more residue and requires more frequent refurbishing, making it less practical for SpaceX's next-generation spacecraft.

What are the main challenges of the full-flow staged combustion cycle in the Raptor engine?

The full-flow staged combustion cycle used in SpaceX's Raptor engine is a cutting-edge design that offers impressive efficiency, but it’s not without its challenges.

One major obstacle is the system's complexity. This approach involves routing both the fuel and oxidizer through turbines, which calls for incredibly precise control of pressures, temperatures, and intricate plumbing. Balancing these variables is crucial to keep the engine running smoothly.

Another significant challenge is thermal management. The intense heat and pressure generated during combustion push materials to their absolute limits. To prevent overheating and potential failures, the design demands advanced cooling techniques capable of withstanding these extreme conditions.

Lastly, being a relatively new technology, the Raptor engine has encountered reliability issues during testing. Some engines have needed adjustments after brief static fire tests, underscoring the ongoing need for fine-tuning to ensure dependable performance during actual missions.

What makes the Raptor engine more suitable for Mars colonization compared to the Merlin engine?

The Raptor engine is a pivotal piece of SpaceX's strategy for Mars colonization, thanks to its cutting-edge reusability and efficiency. Unlike the Merlin engine, the Raptor is built for rapid reuse, which slashes costs and allows for more frequent launches. This is a crucial advantage when it comes to moving people and cargo to Mars on a large scale.

What sets the Raptor apart even further is its use of methane and liquid oxygen (CH₄/LOX) as propellants. These can be produced directly on Mars using the planet's natural resources, enabling spacecraft to refuel on-site. This capability is a game-changer for sustaining long-term missions and aligns perfectly with SpaceX's goal of making life multiplanetary. While the Merlin engine excels at Earth-based missions, its performance and reliance on kerosene make it less practical for the unique challenges of interplanetary travel.

Comments ()